|

Color Proofing

Proofing is the critical link between the

graphic production process and printing.

A proof is the visual contract between the

printer and their client. It is the closest

thing to ink on paper, short of firing up the

printing press.

As defined by several online print-provider

websites, ‘a color proof is used to simulate

how the printed piece will look. Because of

differences in equipment, paper, inks, and

other conditions between color proofing

and production pressroom operations,

a reasonable variation in color between

color proofs and the completed job is to

be expected. When variations of this kind

occur, it will be considered acceptable

performance and the proof becomes a

contract between the client and supplier.’

The three leading proofing technologies

are digital halftone, inkjet, and monitor

proofing. These represent the predominate

technologies in most graphic production

departments. They also represent the

majority of SWOP-certified solutions

currently on the market.

Some readers may argue that toner-based

systems should be included on this list.

Although toner-based technology offers

excellent results, it is not widely considered

to be of high enough quality to be used as a contract proof. Color laser proofs are

commonly used as an intermediate proof to

review content and composition.

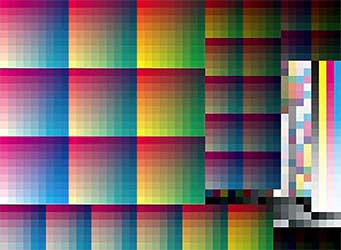

The ECI2002 standard target containing 1485 color patches, one of several types of targets used to characterize (profile) color printing and proofing devices.

Measuring Quality

One of the most respected venues for

evaluating proof quality is the IPA Color

Proofing RoundUP, conducted annually

at the IPA Technical Conference. The

conference’s organizers evaluated nearly

30 color proofing systems this year, based

on the following criteria:

- Visual match to the GRACoL press sheet

- Colorimetric match (Delta E) to the

press sheet using a IT8.7/4 color target.

Monitor-based systems matched the

L*a*b* SWOP calibration test

- Ability to accurately reproduce

multi-channel images accompanied by

a multi-channel ICC source profile

- Match to specific Pantone solids and

Pantone tints

- Costs of the system and media

Digital Halftone

Digital halftone is the Ferrari of the three

proofing technologies. Digital halftone

systems can cost several times that of

other systems. Likewise, digital halftone

proofs cost many times that of other types

of proofs. However, like the Ferrari, you get

what you pay for.

Most digital halftone devices use laser

thermal imaging to produce a proof. A laser

beam strikes a color-coated donor sheet

causing the colorant to be transferred to

a receiver. The receiver is often a transfer

sheet, or carrier. The image is then

transferred from the carrier to the actual

printing stock or other substrate using a

combination of heat and pressure. Donor

materials are coated with pigment-based

colorant that closely simulates the color

characteristics of printing inks.

Digital halftone proofs replicate the halftone

screening method used for offset printing:

screen ruling, dot shape, dot gain, and

screen angle. Therefore, digital halftone

proofs provide a better indication of printed

detail and the possibility of moiré patterns.

Another major advantage of digital halftone

proofs is their ability to be produced on

the same substrate as the actual printed

piece. This is a significant advantage over

inkjet proofs, which are limited to specially

coated stocks, and as a result must

simulate the actual paper color by altering

the overall color of the proof.

In addition to screening and choice of

substrates, digital halftone devices offer

other unique features such as the ability to

produce true metallic colors and print with

opaque white for use on clear and other

specialized substrates.

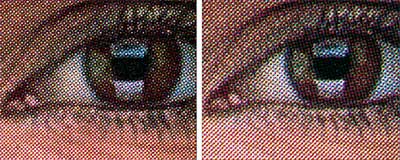

Above Left: The original image, part of Kodak’s Colorflow Press Aim Analysis test form. Image © Kodak

Above Right: An extreme enlargement of an EPSON Stylus® Pro 9600 inkjet proof of the image to the left. Note the fine pattern of ink droplets.

Above Left: An extreme enlargement of a Kodak Approval NX™ digital halftone proof of the same image. Note the line screen pattern, which matches the printed sheet to the right.

Above Right: An extreme enlargement of an actual press sheet, printed on a MAN ROLAND 700 printing press at 150 lpi.

Inkjet

Inkjet has become a reliable and widely

accepted alternative to digital halftone

proofing. Not too long ago most printers

would have balked at being asked to

match an inkjet proof on press. However,

over the past five years, advances in

inkjet technology and color management

software have made inkjet a worthy

alternative to digital halftone technology.

In fact, many printers now provide them to

their customers as a contract proof.

Unlike a digital halftone proof, inkjet proofs

do not reproduce the halftone dots. Tiny

droplets of ink are sprayed from a print

head through a series of small nozzles

onto specially coated paper, which dries

immediately. Advances in inkjet technology

allow for near-continuous tone proofs with

dot sizes of 2 picoliters or less.

While digital halftone devices require

highly-specialized lasers, costly pigmented

donors, and proprietary software, inkjet

devices rely on commercially available

color management and RIP technology

to achieve color fidelity. Using ICC

color profiles, inkjet devices can be

‘tuned’ to accurately simulate varying

printing technologies and substrate

characteristics. For a further explanation

of color management and its application to

proofing, please read the second edition of

The Digital Edge, available on our website.

Monitor Proofing

Often referred to as soft-proofing because

of the lack of a physical or ‘hard’ proof,

true contract-quality monitor proofing only

emerged on the scene about four

years ago. ICS’s Remote Director™

became the first SWOP-certified monitorbased

proofing system in January 2003.

Today SWOP has almost 20 certified

monitor-based systems listed on their

website. This year’s IPA Color Proofing

RoundUP featured seven monitor-based

proofing solutions. Three years ago, only

one monitor-based system participated in

the annual event.

Running on commercially available

hardware, monitor-based systems rely on

advanced color management software to

approximate the brightness, color, and

contrast of a printed piece. This is no small

challenge, matching the characteristics of

transmitted light on a monitor to reflected

light from a printed piece. Monitor-based

proofing systems rely on tightly controlled

room lighting and viewing booth conditions

for accurate color evaluation between

screen and printed piece.

Monitor-based proofing systems have the

ability to provide added features such as

real-time remote viewing, collaborative

review, mark-up, and digital sign-off.

The Future of Proofing

Recent technologies such as PDF, CTP,

and digital printing have dramatically

changed the graphic arts industry, which

includes proofing technologies.

A few years ago the list of proofing

technologies would have included analog

technologies such as Cromalin®, Color

Key™, and MatchPrint™. These were used

to proof color-separated films. Similarly, in

a few years this list may not include any

digital ‘hard’ proofing technologies.

Take for example digital printing, where

it is common to print a single piece for

a customer’s approval as opposed to

generating a proof. Printing one piece with

a digital press is much more cost effective

than with a commercial press. There are no

films, no plates, no make-ready, no time

wasted getting the press ‘up to speed’, and

no wash-up afterwards.

Tighter deadline, shorter budgets, global

print procurement, and falling flat-screen

monitor prices will continue to increase the

use of monitor-based proofing for all types

of printing. Standard technologies such as

PDF, JDF, and ICC color management will

ensure end-to-end quality and consistency.

Lastly and most significantly, newcomers to

the industry, more comfortable with digital

media than their ‘analog’ predecessors, will

readily accept monitor-based proofing.

Gary Stafford is the

President of Lazer Incorporated. As a premier graphic communications

provider, Lazer specializes in digital imaging, design and

mechanical layout, electronic prepress, catalog and packaging

development, Digital Asset Management (DAM) and service,

service, service.

Email: garys@lazerinc.com

Company Profile:

Lazer Incorporated

Company URL:

Back to Columns

page

|